|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

This chapter contains information about the following topics:

A Design Exchange Format (DEF) file contains the design-specific information of a circuit and is a representation of the design at any point during the layout process. The DEF file is an ASCII representation using the syntax conventions described in "Typographic and Syntax Conventions".

For standard-cell-based/ASIC flow tools, floorplanning is part of the design flow. You typically use the various floorplanning commands to interactively create a floorplan. This data then becomes part of the physical data output for the design using the ROWS, TRACKS, GCELLGRID, and DIEAREA statements. You also can manually enter this data into DEF to create the floorplan.

It is legal for a DEF file to contain only floorplanning information, such as ROWS. In many cases, the DEF netlist information is in a separate format, such as Verilog, or in a separate DEF file. It is also common to have a DEF file that only contains a COMPONENTS section to pass placement information.

Note the following information about creating DEF files:

|

DEF statements end with a semicolon ( ; ). You must leave a space before the semicolon. |

|

You must define all objects before you reference them except for the + ORIGINAL argument in the NETS section. |

! " # $ % & ` ( ) * + , / : ; < = > ? @ [ \ ] ^ _ ` { | } ~

A LEF or DEF property string value is contained inside a pair of quotes, like this "<string>". The <string> value can contain any printable ASCII character as shown above, including space, tab, or new-line characters.

Some characters have reserved meanings unless escaped with \.

|

[ ] |

Default special characters for bus bits inside a net or pin name unless overridden by BUSBITCHARS |

|

Default special character for hierarchy inside a net or component name unless overridden by DIVIDERCHAR |

|

|

Matches any sequence of characters for SPECIALNETS or GROUPS component identifiers. |

|

|

Matches any single character for SPECIALNETS or GROUPS component identifiers. |

|

|

The start and end character of a property string value. It has no special meaning for an identifier. |

|

You can use the backslash (\) as an escape character before each of the special characters shown above. When the backslash precedes a character that has a special meaning in LEF or DEF, the special meaning of the character is ignored.

Here are some examples depicting the use of the escape character (\) in identifiers:

|

A DEF file with BUSBITCHARS "[]" and net or pin name: |

|

is the 0th member of bus A |

||

|

A DEF file with DIVIDERCHAR "/" and net or component names like: |

|

is a 3-level hierarchical name, where C is inside B and B is inside A |

||

|

The " character has no special meaning for an identifier. So an identifier would not need a \ before a ". An identifier like: |

name_with_"_in_it

or even

"_name_starts_with_qoute

is legal without a \.

|

An identifier that starts with # would be treated as a comment unless the \ is present like this: |

\#_name_with_hash_for_first_char

Note, the # needs to be preceded by white-space to be treated as a comment char, so it has no special meaning inside an identifier. So an identifier like

name_with_#_in_it

is legal without a \.

|

Pattern matching characters * or % inside SPECIALNETS or GROUPS component identifiers can be disabled like this: |

GROUPS 1 ;

- myGroup i1/i2/\* ...

or

SPECIALNETS 1 ;

- VDD ( i1/i2/\* VDD ) ...

These will match the exact name i1/i2/* and not match i1/i2/i3 or other components starting with i1/i2/.

Note, the * and % have no special meaning in other identifiers, so no \ is needed for them.

|

A real \ char in an identifier needs to be escaped like this: |

name_with_\\_in_it ....

The first \ escapes the second \, so the real name is just name_with_\_in_it.

Properties may have string type values, placed within double quotes ("). However, if you need to use a double quote as a part of the string value itself, you would need to precede it with the escape character (\) to avoid breaking the property syntax. The escape sequence `\"' is converted to `"' during parsing.

The example below depicts the use of the escape character in a quoted property string:

PROPERTY stringQuotedProp "string with \" quote and single backslash \and double backslash \\" ;

The actual value of the property in the database will be:

string with " quote and single backslash and double backslash\

|

The first \ escapes the " so it does not end the property string. |

|

The next \ has no effect on the subsequent a character. |

|

The first \ in \\ escapes the second \ character. This means that the second \ in \\ is treated as a real \ character, and it does not escape the final " character, which ends the property string. |

Note that the other special characters like [ ] / # * % have no special meaning inside a property string and do not need to be escaped.

In DEF syntax, \ is only used to escape characters that have a special meaning if they are not escaped.

Consider the following LEF/DEF header specification:

|

|

|

LEFDEF/[] is equivalent to LEF or DEF with DIVIDERCHAR "/" and BUSBITCHARS "[]" |

|

|

|

LEFDEF|<> is equivalent to LEF or DEF with DIVIDERCHAR "|" and BUSBITCHARS "<>" |

In the following examples, <> are not special characters for LEFDEF/[] files and [] are not special characters for LEFDEF|<> files. Observe how the header settings (listed above) affect the semantic meaning of the names:

|

A<0> with LEFDEF/[] is not equivalent to A<0> with LEFDEF|<> |

|

A<0> with LEFDEF/[] is equivalent to A\<0\> with LEFDEF|<> |

|

A[0] with LEFDEF/[] is equivalent to A<0> with LEFDEF|<> |

For Verilog and DEF equivalence, consider the following DEF header specification:

|

|

|

DEF/[] is equivalent to DEF with DIVIDERCHAR "/" and BUSBITCHARS "[]" |

|

|

|

DEF|<> is equivalent to DEF with DIVIDERCHAR "|" and BUSBITCHARS "<>" |

In the following examples (showing net names), <> are not special characters for DEF/[] files and [] are not special characters for DEF|<> files:

|

A<0> in DEF/[] is equivalent to \A<0> in Verilog |

A<0> in DEF|<> is equivalent to A[0] in Verilog (bit 0 of bus A)

|

A[0] in DEF/[] is equivalent to A[0] in Verilog (bit 0 of bus A) |

A[0] in DEF|<> is equivalent to \A[0] in Verilog

|

A\<0\> in DEF/[] is equivalent to \A<0> in Verilog |

A\<0\> in DEF|<> is equivalent to \A<0> in Verilog

|

A\[0\] in DEF/[] is equivalent to \A[0] in Verilog |

A\[0\] in DEF|<> is equivalent to \A[0] in Verilog *

The following example shows instance path names for Verilog and DEF equivalence:

|

A/B in DEF/[] represents instance path A.B (instance A in the top module, with instance B inside the module referenced by instance A) in Verilog. |

|

A\/B in DEF/[] represents instance \A/B in Verilog. |

|

A\/B/C in DEF/[] represents \A/B .C in Verilog (escaped instance \A/B in the top module, with instance C inside the module referenced by instance \A/B). |

|

The net and instance path A\/B/C/D[0] in DEF/[] will represent \A/B .C.D[0] in Verilog (escaped instance \A/B in the top module, with instance C inside the module referenced by instance \A/B, and bus D in that module with bit 0 being specified). |

The DEF escape \ applies only to the next character and prevents the character from having a special meaning.

The Verilog escape \ affects the complete "token" and is terminated by a trailing white space (" ", Tab, Enter, etc.).

Standard DEF files can contain the following statements and sections. You can define the statements and sections in any order; however, data must be defined before it is used. For example, you must specify the UNITS statement before any statements that use values dependent on UNITS values, and VIAS statements must be defined before statements that use via names. If you specify statements and sections in the following order, all data is defined before being used.

The following definitions describe the syntax arguments for the statements and sections that make up a DEF file. The statements and sections are listed in alphabetical order, not in the order they must appear in a DEF file. For the correct order, see Order of DEF Statements.

|

COMPONENT compName |

Specifies a component with which to associate a blockage. Specify with LAYER layerName to create a blockage on layerName associated with a component. Specify with PLACEMENT to create a placement blockage associated with a component. |

|

DESIGNRULEWIDTH effectiveWidth |

|

|

Specifies that the blockage has a width of effectiveWidth for the purposes of spacing calculations. If you specify DESIGNRULEWIDTH, you cannot specify SPACING. As a lot of spacing rules in advanced nodes no longer just rely on wire width, DESIGNRULEWIDTH is not allowed for 20nm and below nodes. |

|

|

Creates a blockage on the specified layer where metal fill shapes cannot be placed. |

|

|

LAYER layerName |

Note: Cut-layer blockages will prevent vias from being placed in that area. |

|

MASK maskNum |

Specifies which mask for double or triple patterning lithography to use for the specified shapes. The maskNum variable must be a positive integer. Most applications support values of only 1, 2, or 3. Shapes without any defined mask have no mask set (are uncolored). - LAYER metal1 + PUSHDOWN + MASK 1 RECT ( -300 -310 ) ( 320 330 ) #rectangle on mask 1 RECT ( -150 -160 ) ( 170 180 ); #rectangle on mask 1 |

|

Specifies the number of blockages in the design specified in the BLOCKAGES section. |

|

|

PARTIAL maxDensity |

Indicates that the initial placement should not use more than maxDensity percentage of the blockage area for standard cells. Later placement of clock tree buffers, or buffers added during timing optimization ignore this blockage. The maxDensity value is calculated as: standard cell area in blockage area/blockage area <= maxDensity This can be used to reduce the density in a locally congested area, and preserve it for buffer insertion. |

|

POLYGON pt pt pt |

Specifies a sequence of at least three points to generate a polygon geometry. The polygon edges must be parallel to the x axis, the y axis, or at a 45-degree angle. Each POLYGON statement defines a polygon generated by connecting each successive point, and then the first and last points. The pt syntax corresponds to a coordinate pair, such as x y. Specify an asterisk (*) to repeat the same value as the previous x or y value from the last point. |

|

Specifies that the blockage was pushed down into the block from the top level of the design. |

|

|

RECT pt pt |

|

|

Creates a blockage on the specified layer where slots cannot be placed. |

|

|

SPACING minSpacing |

Specifies the minimum spacing allowed between this particular blockage and any other shape. The minSpacing value overrides all other normal LAYER-based spacing rules, including wide-wire spacing rules, end-of-line rules, parallel run-length rules, and so on. A blockage with SPACING is not "seen" by any other DRC check, except the simple check for minSpacing to any other routing shape on the same layer. The minSpacing value cannot be larger than the maximum spacing defined in the SPACING or SPACINGTABLE for that layer. Tools may change larger values to the maximum spacing value with a warning. |

Example 4-1 Blockages Statements

|

The following BLOCKAGES section defines eight blockages in the following order: two metal2 routing blockages, a pushed down routing blockage, a routing blockage attached to component |i4, a floating placement blockage, a pushed down placement blockage, a placement blockage attached to component |i3, and a fill blockage. |

- LAYER metal1

RECT ( -300 -310 ) ( 320 330 )

RECT ( -150 -160 ) ( 170 180 ) ;

- LAYER metal1 + PUSHDOWN

RECT ( -150 -160 ) ( 170 180 ) ;

- LAYER metal1 + COMPONENT |i4

RECT ( -150 -160 ) ( 170 180 ) ;

- PLACEMENT

RECT ( -150 -160 ) ( 170 180 ) ;

- PLACEMENT + PUSHDOWN

RECT ( -150 -160 ) ( 170 180 ) ;

- PLACEMENT + COMPONENT |i3

RECT ( -150 -160 ) ( 170 180 ) ;

- LAYER metal1 + FILLS

RECT ( -160 -170 ) ( 180 190 ) ;

|

The following BLOCKAGES section defines two blockages. One requires minimum spacing of 1000 database units for its rectangle and polygon. The other requires that its rectangle's width be treated as 1000 database units for DRC checking. |

- LAYER metal1

+ SPACING 1000 #RECT and POLYGON require at least 1000 dbu spacing

RECT ( -300 -310 ) ( 320 300 )

POLYGON ( 0 0 ) ( * 100 ) ( 100 * ) ( 200 200 ) ( 200 0 ) ; #Has 45-degree #edge

- LAYER metal1

+ DESIGNRULEWIDTH 1000 #Treat the RECT as 1000 dbu wide for DRC checking

RECT ( -150 -160 ) ( 170 180 ) ;

If one of the bus bit characters appears in a DEF name as a regular character, you must use a backslash (\) before the character to prevent the DEF reader from interpreting the character as a bus bit delimiter.

If you do not specify the BUSBITCHARS statement in your DEF file, the default value is "[]".

Example 4-2 Component Mask Shift

The following example indicates that any given component can shift the mask on layers M3, M2, VIA1, or M1:

COMPONENTMASKSHIFT M3 M2 VIA1 M1 ;

This layer list is used to interpret the + MASKSHIFT shiftLayerMasks value for a specific component as shown in the example given below:

+ MASKSHIFT 1102 #M3 shifted by 1, M2 by 1, VIA1 by 0, M1 by 2

...

For details on components, see the Components section.

Defines design components, their location, and associated attributes.

|

Specifies the component name in the design, which is an instance of modelName, the name of a model defined in the library. A modelName must be specified with each compName. |

|

|

COVER pt orient |

Specifies that the component has a location and is a part of a cover macro. A COVER component cannot be moved by automatic tools or interactive commands. You must specify the component's location and its orientation. |

|

EEQMASTER macroName |

|

|

FIXED pt orient |

|

|

HALO [SOFT] left bottom right top |

|

|

Specifies a placement blockage around the component. The halo extends from the LEF macro's left edge(s) by left, from the bottom edge(s) by bottom, from the right edge(s) by right, and from the top edge(s) by top. The LEF macro edges are either defined by the rectangle formed by the MACRO SIZE statement, or, if OVERLAP obstructions exist (OBS shapes on a layer with TYPE OVERLAP), the polygon formed by merging the OVERLAP shapes. If SOFT is specified, the placement halo is honored only during initial placement; later phases, such as timing optimization or clock tree synthesis, can use the halo area. This can be used to preserve certain areas (such as small channels between blocks) for buffer insertion. |

|

|

MASKSHIFT shiftLayerMasks |

|

|

The shiftLayerMasks variable is a hex-encoded digit, with one digit per multi-mask layer: ...<thirdLayerShift><secondLayerShift><bottomLayerShift> |

|

|

The bottomLayerShift value is the mask-shift for the bottom-most multi-mask layer defined in the COMPONENTMASKSHIFT statement. The secondMaskShift, thirdMaskShift, and so on, are the shift values for each layer in order above the bottom-most multi-mask layer. The missing digits indicate that no shift is needed so 002 and 2 have the same meaning. For 2-mask layers, the LayerShift value must be 0 or 1 and indicates: 1 - Shift the mask colors by 1 (mask 1->2, and 2->1) For 3-mask layers, the LayerShift value can be 0, 1, 2, 3, 4, or 5 that indicates: 1 - Shift by 1 (1->2, 2->3, 3->1) 2 - Shift by 2 (1->3, 2->1, 3->2) 3 - Mask 1 is fixed, swap 2 and 3 4 - Mask 2 is fixed, swap 1 and 3 5 - Mask 3 is fixed, swap 1 and 2 The purpose of 3, 4, 5 is for standard cells that have a fixed power-rail mask color, but the pins between the power-rails can still be shifted. Suppose you had a standard cell with mask 1 power rails, and three signal pins on mask 1, 2, and 3. A LayerShift of 3, will keep the mask 1 power rails and signal pin fixed on mask 1, while mask 2 and mask 3 signal pin shapes will swap mask colors. |

|

Example 4-3 Mask Shift Layers for Components

The following example shows a LEF section that has a three-mask layer defined for M1, and two-mask layer defined for layers VIA1 and M2:

COMPONENTMASKSHIFT M2 VIA1 M1 ;

+ MASKSHIFT 2 #M1 layer masks are shifted by 2, no shift for others

...

+ MASKSHIFT 103 ##M1 layer has shift 3, VIA1 0, M2 1

...

Example 4-4 Component Halo

The following statement creates a placement blockage for a "U-shaped" LEF macro, as illustrated in Figure 4-1 :

- i1/i2

+ PLACED ( 0 0 ) N

+ HALO 100 0 50 200 ;

Figure 4-1 Component Halo

Specifies the number of components defined in the COMPONENTS section.

PLACED pt orient

Specifies that the component has a location, but can be moved using automatic layout tools. You must specify the component's location and orientation.

PROPERTY propName propVal

Specifies a numerical or string value for a component property defined in the PROPERTYDEFINITIONS statement. The propName you specify must match the propName listed in the PROPERTYDEFINITIONS statement.

REGION regionName

Specifies a region in which the component must lie. regionName specifies a region already defined in the REGIONS section. If the region is smaller than the bounding rectangle of the component itself, the DEF reader issues an error message and ignores the argument. If the region does not contain a legal location for the component, the component remains unplaced after the placement step.

ROUTEHALO haloDist minLayer maxLayer

Specifies that signal routing in the "halo area" around the block boundary should be perpendicular to the block edge in order to reach the block pins. The halo area is the area within haloDist of the block boundary (see the Figure below). A routing-halo is intended to be used to minimize cross coupling between routing at the current level of the design, and routing inside the block. It has no effect on power routing. Note that this also means it is allowed to route in the "halo corners" because routing in the "halo corner" is not adjacent to the block boundary, and will not cause any significant cross-coupling with routing inside the block.

The routing halo exists for the routing layers between minLayer and maxLayer. The layer you specify for minLayer must be a lower routing layer than maxLayer.

Type: Integer, specified in DEF database units (haloDist); string that matches a LEF routing layer name (minLayer and maxLayer)

Example 4-5 Route Halo Example

For a U-shaped macro, the following component description results in the halo shown in Figure 4-2.

- il/i2

+ PLACED ( 0 0 ) N

+ ROUTEHALO 100 metal1 metal3 ;

Figure 4-2 Route Halo

SOURCE {NETLIST | DIST | USER | TIMING}

Specifies the source of the component.

Value: Specify one of the following:

|

Component is generated by the user for some user-defined reason. |

Specifies that the component does not have a location.

WEIGHT weight

Specifies the weight of the component, which determines whether or not automatic placement attempts to keep the component near the specified location. weight is only meaningful when the component is placed. All non-zero weights have the same effect during automatic placement.

Default: 0

Example 4-6 Die Area Statements

The following statements show various ways to define the die area.

DIEAREA ( 0 0 ) ( 100 100 ) ; #Rectangle from 0,0 to 100,100

DIEAREA ( 0 0 ) ( 0 100 ) ( 100 100 ) ( 100 0 ) ; #Same rectangle as a polygon

DIEAREA ( 0 0 ) ( 0 100 ) ( 50 100 ) ( 50 50 ) ( 100 50 ) ( 100 0 ) ; #L-shaped polygon

DIVIDERCHAR "/" ;

If the divider character appears in a DEF name as a regular character, you must use a backslash (\) before the character to prevent the DEF reader from interpreting the character as a hierarchy delimiter.

If you do not specify the DIVIDERCHAR statement in your LEF file, the default value is "/".

Defines the contents of the extension.

"tag"

Identifies the extension block. You must enclose tag in quotes.

Example 4-7 Extension Statement

CREATOR "company name"

DATE "timestamp"

REVISION "revision number"

|

LAYER layerName |

|

|

MASK maskNum |

Specifies which mask for double or triple patterning lithography to use for the given rectangles or polygons. The maskNum variable must be a positive integer. Most applications support values of 1, 2, or 3 only. Shapes without any defined mask have no mask setting (are uncolored). |

|

MASK viaMaskNum |

The viaMaskNum variable is a hex-encoded three digit value of the form: <topMaskNum><cutMaskNum><bottomMaskNum> For example, MASK 113 means that the top metal and cut layer maskNum is 1, and the bottom metal layer maskNum is 3. A value of 0 means the shape on that layer has no mask assignment (is uncolored), so 013 means the top layer is uncolored. If either the first or second digit is missing, they are assumed to be 0, so 013 and 13 mean the same thing. Most applications support maskNums of 0, 1, 2, or 3 for double or triple patterning. The topMaskNum and bottomMaskNum variables specify which mask the corresponding metal shape belongs to. The via-master metal mask values have no effect. For the cut layer, the cutMaskNum defines the mask for the bottom-most, and then the left-most cut. For multi-cut vias, the via-instance cut masks are derived from the via-master cut mask values. The via-master must have a mask defined for all the cut shapes and every via-master cut mask is "shifted" (from 1 to 2, 2 to1 for two mask layers, and from 1 to 2, 2 to 3, and 3 to 1 for three mask layers) so the lower-left cut matches the cutMaskNum value. Similarly, for the metal layer, the topMaskNum/bottomMaskNum would define the mask for the bottom-most, then leftmost metal shape. For multiple disjoint metal shapes, the via-instance metal masks are derived from the via-master metal mask values. The via-master must have a mask defined for all of the metal shapes, and every via-master metal mask is "shifted" (1->2, 2->1 for two mask layers, 1->2, 2->3, 3->1 for three mask layers) so the lower-left cut matches the topMaskNum/bottomMaskNum value. |

|

Specifies the number of LAYER statements in the FILLS statement, not the number of rectangles. |

|

|

Indicates that the FILL shapes require OPC correction during mask generation. |

|

|

POLYGON pt pt pt |

Specifies a sequence of at least three points to generate a polygon geometry. The polygon edges must be parallel to the x axis, the y axis, or at a 45-degree angle. Each POLYGON statement defines a polygon generated by connecting each successive point, and then the first and last points. The pt syntax corresponds to a coordinate pair, such as x y. Specify an asterisk (*) to repeat the same value as the previous x or y value from the last point. |

|

RECT pt pt |

Specifies the lower left and upper right corner coordinates of the fill geometry. |

|

VIA viaName pt |

Places the via named viaName at the specified (x y) location (pt). viaName must be a previously defined via in the DEF VIAS or LEF VIA section. |

Example 4-8 Fills Statements

|

The following FILLS statement defines fill geometries for layers metal1 and metal2: |

FILLS 2 ;

- LAYER metal1

RECT ( 1000 2000 ) ( 1500 4000 )

RECT ( 2000 2000 ) ( 2500 4000 )

RECT ( 3000 2000 ) ( 3500 4000 ) ;

- LAYER metal2

RECT ( 1000 2000 ) ( 1500 4000 )

RECT ( 1000 4500 ) ( 1500 6500 )

RECT ( 1000 7000 ) ( 1500 9000 )

RECT ( 1000 9500 ) ( 1500 11500 ) ;

END FILLS

|

The following FILLS statement defines two rectangles and one polygon fill geometries: |

FILLS 1 ;

-LAYER metal1

RECT ( 100 200 ) ( 150 400 )

POLYGON ( 100 100 ) ( 200 200 ) ( 300 200 ) ( 300 100 )

RECT ( 300 200 ) ( 350 400 ) ;

END FILLS

|

Shapes on the TRIMMETAL layers are written out in the FILLS section in DEF in the following format: |

- LAYER TM1 + MASK x RECT (x x) (x x) ;

The following FILLS statement defines two rectangular shapes on the TRIMMETAL layer TM1, which is defined in a property statement in the masterslice layer section in LEF:

FILLS 2 ;

- LAYER TM1 + MASK 1 RECT (30 28) (33 38)

- LAYER TM1 + MASK 2 RECT (36 23) (39 33)

...

END FILLS

Figure 4-3 Trim Metal Layer Shapes in the FILLS Section

|

The following FILLS statement defines two rectangles and two via fill geometries for layer metal1. The rectangles and one of the via fill shapes require OPC correction. |

FILLS 3 ;

-LAYER metal1 + OPC

RECT ( 0 0 ) ( 100 100 )

RECT ( 200 200 ) ( 300 300 ) ;

-VIA via26

( 500 500 )

( 800 800 ) ;

-VIA via28 + OPC

( 900 900 ) ;

END FILLS

Example 4-9 Multi-Mask Patterns for Fills

The following example shows multi-mask patterning for fills:

- LAYER M1 + MASK 1 RECT ( 10 10 ) ( 11 11 ) ; #RECT on MASK 1

- LAYER M2 RECT ( 10 10 ) ( 11 11 ) ; #RECT is uncolored

- VIA VIA1_1 + MASK 031 ( 10 10 ) ; #VIA with top-cut-bot mask 031

|

M1 rectangle shape is on MASK 1 |

|

M2 rectangle shape has no mask set and is uncolored |

|

VIA1_1 via will have: |

|

|

|

no mask set for the top metal shape - it is uncolored (topMaskNum is 0 in the 031 value). Note that the via-master color of the top metal shape does not matter. |

|

|

|

mask 1 for the bottom metal shape (bottomMaskNum is 1 in the 031 value) |

|

|

|

for the cut layer, the bottom-most, and then the left-most cut of the via-instance is mask 3. The mask for the other cuts of the via-instance are derived from the via-master by "shifting" the via-master cut masks to match. So if the via-master's bottom- left cut is MASK 1, then the via-master cuts on mask 1 become mask 3 for the via-instance, and similarly cuts on 2 become 1, and cuts on 3 become 2. See Figure 4-11. |

Defines the gcell grid for a standard cell-based design. Each GCELLGRID statement specifies a set of vertical (x) and horizontal (y) lines, or tracks, that define the gcell grid.

Typically, the GCELLGRID is automatically generated by a particular router, and is not manually created by the designer.

DO numColumns+1

Specifies the number of columns in the grid.

DO numRows+1

Specifies the number of rows in the grid.

STEP space

Specifies the spacing between tracks.

X start, Y start

Specify the location of the first vertical (x) and first horizontal (y) track.

For example, the grid formed by the following two GCELLGRID statements creates gcells that are all the same size (100 x 200 in the following):

GCELLGRID X 1000 DO 101 STEP 100 ;

GCELLGRID Y 1000 DO 101 STEP 200 ;

A gcell grid in which all gcells are the same size is called a uniform gcell grid. Adding GCELLGRID statements can increase the granularity of the grid, and can also result in a nonuniform grid, in which gcells have different sizes.

For example, adding the following two statements to the above grid generates a nonuniform grid:

GCELLGRID X 3050 DO 61 STEP 100 ;

GCELLGRID Y 5100 DO 61 STEP 200 ;

Every track segment must belong to a gcell, so gcell grids have the following restrictions:

Gcells grids also have the following restrictions:

|

Each GCELLGRID statement must define two lines. |

Specifies the components that make up the group. Do not assign any component to more than one group. You can specify any of the following:

|

|

|

A list of component names separated by spaces, for example, I01 I02 C3204 C3205 |

|

|

|

A pattern for a set of components, for example, IO* and C320* |

Note: An empty group with no component names is allowed.

Specifies the name for a group of components.

Specifies the number of groups defined in the GROUPS section.

PROPERTY propName propVal

Specifies a numerical or string value for a group property defined in the PROPERTYDEFINITIONS statement. The propName you specify must match the propName listed in the PROPERTYDEFINITIONS statement.

REGION regionName

Specifies a rectangular region in which the group must lie. regionName specifies a region previously defined in the REGIONS section. If region restrictions are specified in both COMPONENT and GROUP statements for the same component, the component restriction overrides the group restriction.

Lists a historical record about the design. Each line indicates one record. Any text excluding a semicolon (;) can be included in anyText. The semicolon terminates the HISTORY statement. Linefeed and Return do not terminate the HISTORY statement. Multiple HISTORY lines can appear in a file.

Defines netlist connectivity and regular-routes for nets containing regular pins. These routes are normally created by a signal router that can rip-up and repair the routing. The SPECIALNETS statement defines netlist connectivity and routing for special-routes that are created by "special routers" or "manually" and should not be modified by a signal router. Special routes are normally used for power-routing, fixed clock-mesh routing, high-speed buses, critical analog routes, or flip-chip routing on the top-metal layer to bumps.

Input arguments for a net can appear in the NETS section or the SPECIALNETS section. In case of conflicting values, the DEF reader uses the last value encountered. NETS and SPECIALNETS statements can appear more than once in a DEF file. If a particular net has mixed wiring or pins, specify the special wiring and pins first.

compName pinName

Specifies the name of a regular component pin on a net or a subnet. LEF MUSTJOIN pins, if any, are not included; only the master pin (that is, the one without the MUSTJOIN statement) is included. If a subnet includes regular pins, the regular pins must be included in the parent net.

COVER pt orient

Specifies that the pin has a location and is a part of the cover macro. A COVER pin cannot be moved by automatic tools or by interactive commands. You must specify the pin's location and orientation.

ESTCAP wireCapacitance

Specifies the estimated wire capacitance for the net. ESTCAP can be loaded with simulation data to generate net constraints for timing-driven layout.

FIXED pt orient

Specifies that the pin has a location and cannot be moved by automatic tools, but can be moved by interactive commands. You must specify the pin's location and orientation.

Indicates that the bump net cannot be reassigned to a different pin.

It is legal to have a pin without geometry to indicate a logical connection, and to have a net that connects that pin to two other instance pins that have geometry. Area I/Os have a logical pin that is connected to a bump and an input driver cell. The bump and driver cell have pin geometries (and, therefore, should be routed and extracted), but the logical pin is the external pin name without geometry (typically the Verilog pin name for the chip).

Because bump nets are usually routed with special routing, they also can be specified in the SPECIALNETS statement. If a net name appears in both the NETS and SPECIALNETS statements, the FIXEDBUMP keyword also should appear in both statements. However, the value only exists once within a given application's database for the net name.

Because DEF is often used incrementally, the last value read in is used. Therefore, in a typical DEF file, if the same net appears in both statements, the FIXEDBUMP keyword (or lack of it) in the NETS statement is the value that is used, because the NETS statement is defined after the SPECIALNETS statement.

For an example specifying the FIXEDBUMP keyword, see "Fixed Bump".

FREQUENCY frequency

Specifies the frequency of the net, in hertz. The frequency value is used by the router to choose the correct number of via cuts required for a given net, and by validation tools to verify that the AC current density rules are met. For example, a net described with + FREQUENCY 100 indicates the net has 100 rising and 100 falling transitions in 1 second.

Type: Float

LAYER layerName

Specifies the layer on which the virtual pin lies.

MUSTJOIN (compName pinName)

Specifies that the net is a mustjoin. If a net is designated MUSTJOIN, its name is generated by the system. Only one net should connect to any set of mustjoin pins. Mustjoin pins for macros are defined in LEF. The only reason to specify a MUSTJOIN net in DEF (identified arbitrarily by one of its pins) is to specify prewiring for the MUSTJOIN connection.

Otherwise, nets are generated automatically where needed for mustjoin connections specified in the library. If the input file specifies that a mustjoin pin is connected to a net, the DEF reader connects the set of mustjoin pins to the same net. If the input file does not specify connections to any of the mustjoin pins, the DEF reader creates a local MUSTJOIN net.

Specifies the name for the net. Each statement in the NETS section describes a single net. There are two ways of identifying the net: netName or MUSTJOIN. If the netName is given, a list of pins to connect to the net also can be specified. Each pin is identified by a component name and pin name pair (compName pinName) or as an I/O pin (PIN pinName). Parentheses ensure readability of output. The keyword MUSTJOIN cannot be used as a netName.

NONDEFAULTRULE ruleName

By default the width of any route segment in the NETS regularWiring section is defined by the default width (LEF WIDTH statement value for the routing layer).

This keyword specifies a nondefault rule to use instead of the default rule when creating the net and wiring. When specified with SUBNET, identifies the nondefault rule to use when creating the subnet and its wiring.

The width of any route segment is defined by the corresponding NONDEFAULTRULE WIDTH for that layer.

Wrong-way Width Rules

Some technologies required larger widths for wrong-way routing than in the preferred direction. If the wrong-way width is larger than the default or NDR width, then the wrong-way width is used for wrong-way routes on that layer. The implicit routing extension is still half of the default or NDR width, even for wrong-way routes.

The following LEF DRC rules allow a WRONGDIRECTION keyword that defines wrong-way widths that will affect the width of any wrong-way routes in the DEF NETS section:

LEF58_WIDTH

LEF58_WIDTHTABLE

LEF58_SPANLENGTHTABLE

See the "Impact of Wrong-way Width Rules " section for examples and more details.

Specifies the number of nets defined in the NETS section.

ORIGINAL netName

Specifies the original net partitioned to create multiple nets, including the net being defined.

PATTERN {BALANCED | STEINER | TRUNK | WIREDLOGIC}

Specifies the routing pattern used for the net.

Default: STEINER

Value: Specify one of the following:

|

Used in ECL designs to connect output and mustjoin pins before routing to the remaining pins. |

PIN pinName

Specifies the name of an I/O pin on a net or a subnet.

PLACED pt orient

Specifies that the pin has a location, but can be moved during automatic layout. You must specify the pin's location and orientation.

PROPERTY propName propVal

Specifies a numerical or string value for a net property defined in the PROPERTYDEFINITIONS statement. The propName you specify must match the propName listed in the PROPERTYDEFINITIONS statement.

Specifies the regular physical wiring for the net or subnet. For regular wiring syntax, see "Regular Wiring Statement".

SHIELDNET shieldNetName

Specifies the name of a special net that shields the regular net being defined. A shield net for a regular net is defined earlier in the DEF file in the SPECIALNETS section.

SOURCE {DIST | NETLIST | TEST | TIMING | USER}

Specifies the source of the net. The value of this field is preserved when input to the DEF reader.

Value: Specify one of the following:

SUBNET subnetName

Names and defines a subnet of the regular net netName. A subnet must have at least two pins. The subnet pins can be virtual pins, regular pins, or a combination of virtual and regular pins. A subnet pin cannot be a mustjoin pin.

Used by some tools to indicate that the pin is part of a synthesized scan chain.

USE {ANALOG | CLOCK | GROUND | POWER | RESET | SCAN | SIGNAL | TIEOFF}

Specifies how the net is used.

Value: Specify one of the following:

VPIN vpinName pt pt

Specifies the name of a virtual pin, and its physical geometry. Virtual pins can be used only in subnets. A SUBNET statement refers to virtual pins by the vpinName specified here. You must define each virtual pin in a + VPIN statement before you can list it in a SUBNET statement.

Example 4-10 Virtual Pin

The following example defines a virtual pin:

+ VPIN M7K.v2 LAYER MET2 ( -10 -10 ) ( 10 10 ) FIXED ( 10 10 )

+ SUBNET M7K.2 ( VPIN M7K.v2 ) ( /PREG_CTRL/I$73/A I )

NONDEFAULTRULE rule1

ROUTED MET2 ( 27060 341440 ) ( 26880 * ) ( * 213280 )

M1M2 ( 95040 * ) ( * 217600 ) ( 95280 * )

NEW MET1 ( 1920 124960 ) ( 87840 * )

COVER MET2 ( 27060 341440 ) ( 26880 * )

WEIGHT weight

Specifies the weight of the net. Automatic layout tools attempt to shorten the lengths of nets with high weights. A value of 0 indicates that the net length for that net can be ignored. The default value of 1 specifies that the net should be treated normally. A larger weight specifies that the tool should try harder to minimize the net length of that net.

For normal use, timing constraints are generally a better method to use for controlling net length than net weights. For the best results, you should typically limit the maximum weight to 10, and not add weights to more than 3 percent of the nets.

Default: 1

Type: Integer

XTALK class

Specifies the crosstalk class number for the net. If you specify the default value (0), XTALK will not be written to the DEF file.

Default: 0

Type: Integer

Value: 0 to 200

Specifies regular wiring for the net.

Specifies that the wiring cannot be moved by either automatic layout or interactive commands. If no wiring is specified for a particular net, the net is unrouted. If you specify COVER, you must also specify layerName.

Specifies that the wiring cannot be moved by automatic layout, but can be changed by interactive commands. If no wiring is specified for a particular net, the net is unrouted. If you specify FIXED, you must also specify layerName.

Specifies the layer on which the wire lies. You must specify layerName if you specify COVER, FIXED, ROUTED, or NEW. Specified layers must be routable; reference to a cut layer generates an error.

NEW layerName

Indicates a new wire segment (that is, there is no wire segment between the last specified coordinate and the next coordinate), and specifies the name of the layer on which the new wire lies. Noncontinuous paths can be defined in this manner.

Specifies that the last wide segment of the net is not shielded. If the last segment is not shielded, and is tapered, specify TAPER under the LAYER argument, instead of NOSHIELD.

Specifies that the wiring can be moved by the automatic layout tools. If no wiring is specified for a particular net, the net is unrouted. If you specify ROUTED, you must also specify layerName. An example of DEF NETS routing is shown in DEF NETS Examples.

Defines the center line coordinates of the route on layerName. For information about using routing points, see "Defining Routing Points".

As described above, the width of the routes is defined by the default width (e.g., LEF WIDTH statement on the routing layer) or a NONDEFAULTRULE width for the routing layer. In addition, some technologies require larger widths for wrong-way routes that may increase the width. See the "Impact of Wrong-way Width Rules " section for more details.

The routingPoints syntax is defined as follows:

{ ( x y [extValue] )

{[MASK maskNum] ( x y [extValue] )

|[MASK viaMaskNum] viaName [orient]

|[MASK maskNum] RECT ( deltax1 deltay1 deltax2 deltay2 )

| VIRTUAL ( x y ) } } ...

|

Specifies the amount by which the wire is extended past the endpoint of the segment. The extension value must be greater than or equal to 0 (zero). Some tools only allow 0 or the WIREEXTENSION value from the LAYER or NONDEFAULTRULE statement. |

||

|

MASK maskNum |

||

|

Specifies which mask for double or triple patterning lithography to use for the next wire or RECT. The maskNum variable must be a positive integer - most applications support values of 1, 2, or 3 only. Shapes without any defined mask have no mask set (that is, they are uncolored). |

||

|

MASK viaMaskNum |

||

|

The viaMaskNum variable is a hex-encoded three-digit value of the form: <topMaskNum><cutMaskNum><bottomMaskNum> For example, MASK 113 means that the top metal and cut layer maskNum is 1, and the bottom metal layer maskNum is 3. A value of 0 means that the shape on the layer has no mask assignment (is uncolored), so 013 means the top layer is uncolored. If either the first or second digit is missing, they are assumed to be 0, so 013 and 13 mean the same thing. Most applications support maskNums of 0, 1, 2, or 3 only for double or triple patterning. |

||

|

The topMaskNum and bottomMaskNum variables specify which mask the corresponding metal shape belongs to. The via-master metal mask values have no effect. For the cut layer, the cutMaskNum variable defines the mask for the bottom-most, and then the left-most cut. For multi-cut vias, the via-instance cut masks are derived from the via-master cut mask values. The via-master must have a mask defined for all the cut shapes and every via-master cut mask is "shifted" (from 1 to 2, and 2 to 1 for two mask layers, and from 1 to 2, 2 to 3, and 3 to1 for three mask layers), so the lower-left cut matches the cutMaskNum value. Similarly, for the metal layer, the topMaskNum/bottomMaskNum would define the mask for the bottom-most, then leftmost metal shape. For multiple disjoint metal shapes, the via-instance metal masks are derived from the via-master metal mask values. The via-master must have a mask defined for all of the metal shapes, and every via-master metal mask is "shifted" (1->2, 2->1 for two mask layers, 1->2, 2->3, 3->1 for three mask layers) so the lower-left cut matches the topMaskNum/bottomMaskNum value. |

||

|

Specifies the orientation of the viaName that precedes it, using the standard DEF orientation values of N, S, E, W, FN, FS, FE, and FW (See "Specifying Orientation" ). If you do not specify orient, N (North) is the default non-rotated value used. All other orientation values refer to the flipping or rotation around the via origin (the 0,0 point in the via shapes). The via origin is still placed at the (x y) value given in the routing statement just before the viaName. |

||

|

RECT ( deltax1 deltay1 deltax2 deltay2 ) |

||

|

Indicates that a rectangle is created from the previous ( x y ) routing point using the delta values. The RECT values leave the current point and layer unchanged. |

||

|

Specifies a via to place at the last point. If you specify a via, layerName for the next routing coordinates (if any) is implicitly changed to the other routing layer for the via. For example, if the current layer is metal1, a via12 changes the layer to metal2 for the next routing coordinates. |

||

|

VIRTUAL ( x y ) |

||

|

Indicates that there is a virtual (non-physical zero-width) connection between the previous point and the new ( x y ) point. An '*' indicates that the x or y value is to be used from the previous point. The layer remains unchanged. You can use this keyword to retain the symbolic routing graph. |

||

|

( x y ) |

Specifies the route coordinates. You cannot specify a route with zero length. For more information, see "Specifying Coordinates". |

|

STYLE styleNum

Specifies a previously defined style from the STYLES section in this DEF file. If a style is specified, the wire's shape is defined by the center line coordinates and the style.

Specifies that the next contiguous wire segment on layerName is created using the default rule.

TAPERRULE ruleName

Specifies that the next contiguous wire segment on layerName is created using the specified nondefault rule.

Example 4-11 Multi-mask Patterns for Routing Points

The following example shows a routing statement that specifies three-mask layers M1 and VIA1, and a two-mask layer M2:

+ ROUTED M1 (10 0 ) MASK 3 (10 20 ) VIA1_1

NEW M2 ( 10 10 ) (20 10) MASK 1 ( 20 20 ) MASK 031 VIA1_2 ;

|

M1 wire shape (10 0) to (10 20) belongs to mask 3 |

|

VIA1_1 via has no preceding MASK statement so all the metal and cut shapes have no mask and are uncolored |

|

first NEW M2 wire shape (10 10) to (20 10) has no mask set and is uncolored |

|

second M2 wire shape (20 10) to (20 20) is on mask 1 |

|

VIA1_2 via has a MASK 031 (it can be MASK 31 also) so: |

|

|

|

topMaskNum is 0 in the 031 value, so no mask is set for the top metal (M2) shape |

|

|

|

bottomMaskNum is 1 in the 031 value, so mask 1 is used for the bottom metal (M1) shape |

|

|

|

cutMaskNum is 3 in the 031 value, so the bottom-most, and then the left-most cut of the via-instance is mask 3. The mask for the other cuts of the via-instance are derived from the via-master by "shifting" the via-master's cut masks to match. So if the via-master's bottom-left cut is mask 1, then the via-master cuts on mask 1 become mask 3 for the via-instance, and similarly cuts on 2 shift to 1, and cuts on 3 shift to 2, as shown in Figure 4-4. |

Figure 4-4 Via-master multi-mask patterns

Example 4-12 Routing Points - Usage of Virtual and Rect

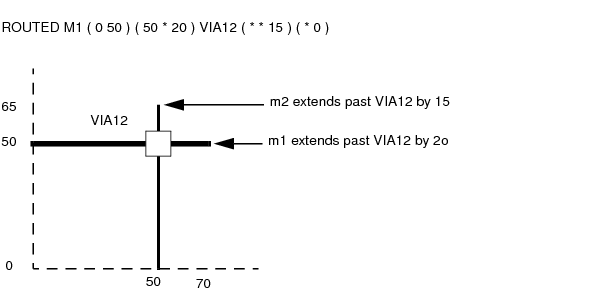

Figure 4-5 shows the results of the following routing statement:

+ ROUTED M1 ( 0 0 ) ( 5 0 ) VIRTUAL ( 7 1 ) RECT ( -3 0 -1 2 ) ( 7 7 ) ;

Figure 4-5 Routing Points - Usage of Virtual and Rect

Routing points define the center line coordinates of the route for a specified layer. Routes that are 90 degrees, have a width defined by the routing rule for this wire, and extend from one coordinate (x y) to the next coordinate.

If either endpoint has an extension value (extValue), the wire is extended by that amount past the endpoint. Some applications require the extension value to be 0, half of the wire width, or the same as the routing rule wire extension value. If you do not specify an extension value, the default value of half of the wire width is used.

If the wire segment is a 45-degree edge, and no STYLE is specified, the default octagon style is used for the endpoints. The routing rule width must be an even multiple of the manufacturing grid in order to keep all of the coordinates of the resulting outer wire boundary on the manufacturing grid.

If a STYLE is defined for 90-degree or 45-degree routes, the routing shape is defined by the center line coordinates and the style. No corrections, such as snapping to manufacturing grid, can be applied, and any extension values are ignored. The DEF file should contain values that are already snapped, if appropriate. The routing rule width indicates the desired user width, and represents the minimum allowed width of the wire that results from the style when the 45-degree edges are properly snapped to the manufacturing grid.

To maximize compactness of the design files, the coordinates allow for the asterisk ( * ) convention. Here, ( x * ) indicates that the y coordinate last specified in the wiring specification is used; ( * y ) indicates that the x coordinate last specified is used. Use

( * * extValue ) to specify a wire extension at a via.

( 100 200 ) ( 200 200 ) ( 200 500 )

The following sequence is an equivalent path:

( 100 200 ) ( 200 * ) ( * 500 )

The following sequence is not valid because it represents a nonorthogonal segment.

( 100 200 ) ( 300 500 )

The following LEF DRC rules allow a WRONGDIRECTION keyword that defines wrong-way widths that will affect the width of any wrong-way routes in the DEF NETS section:

|

Defines the default routing width to use for all regular wiring |

|

|

Defines all the allowable legal widths on the routing layer. |

|

The full syntax for WIDTHTABLE and SPANLENGTHTABLE have an optional ORTHOGONAL keyword or ORTHOGONAL keyword with a value. The ORTHOGONAL keyword and any value after it can be ignored, and has no effect on DEF NETS routing interpretation.

The full syntax for these rules is:

For more information on LEF width rules, see Layer(Routing) section in the "LEF Syntax" chapter in the LEF/DEF Language Reference.

Example 4-13 Impact of default and nondefault rules on wrong-way segment

|

This following example shows how LEF width rules will affect the width of any wrong-way routes in the DEF NETS section. An example of each type of rule (WIDTH, WIDTHTABLE, and SPANLENGTHTABLE) is shown below for METAL2: |

LAYER METAL2

...

DIRECTION VERTICAL ;

#0.6 is the default routing rule width in the vertical direction

WIDTH 0.06 ;

#wrong direction (horizontal) metal width must be >= 0.12

PROPERTY LEF58_WIDTH

"WIDTH 0.12 WRONGDIRECTION ; " ;

...

END METAL2

or

LAYER METAL2

...

DIRECTION VERTICAL ;

#0.06 is the default routing rule width in the vertical direction

WIDTH 0.06 ;

#wrong direction (horizontal) metal width must be 0.12, 0.16 or >= 0.20

PROPERTY LEF58_WIDTHTABLE

"WIDTHTABLE 0.06 0.08 0.12 0.16 0.20 ;

WIDTHTABLE 0.12 0.16 0.20 WRONGDIRECTION ; " ;

...

END METAL2

or

LAYER METAL2

...

DIRECTION VERTICAL ;

#0.06 is the default routing rule width in the vertical direction

WIDTH 0.06 ;

#wrong direction (horizontal) metal width must be 0.12, 0.16 or >= 0.20

PROPERTY LEF58_SPANLENGTHTABLE

"SPANLENGTHTABLE 0.06 0.08 0.12 0.16 0.20 ;

SPANLENGTHTABLE 0.12 0.16 0.20 WRONGDIRECTION ; " ;

...

END METAL2

For the above rules, any METAL2 vertical routes are in the preferred direction so they will have the normal widths and extensions as given by the default rule width, or the NONDEFAULTRULE width definition. The horizontal routes are in the wrong-direction, so they will use the first WRONGDIRECTION value in the rules above, that is greater than or equal to the preferred-direction width.

If the rule width is larger than the largest wrong-direction value, then the wrong-direction width is the same as the rule width as shown for NDR7 below.

The table below shows examples of different routing rule widths and the corresponding vertical and horizontal route widths and extensions for the WIDTHTABLE and SPANLENGTHTABLE rules shown above. They both have 0.12, 0.16, and 0.20 as the legal WRONGDIRECTION width values.

For example, the default rule in the table shows that a vertical route in the NETS section will have a width of 0.06 μm with extension of 0.03 μm, while a horizontal route will have a wrong-way width of 0.12 μm with extension 0.03 μm, as shown in the DEF NETS routing example below:

- NET1 (...)

+ ROUTED METAL2 ( 1 0 ) ( 1 2 ) ( 3 2 ) ( 3 4 ) ;

Figure 4-6 Default rule on wrong way segment

|

NDR1 has a width of 0.08 μm, so it will use the wrong-way width of 0.12, because 0.8 is less than or equal to 0.12 (the first wrong-direction width value). So a vertical route will have a width of 0.08 μm with extension of 0.04 μm on a vertical route, while a horizontal route will have a width of 0.12 μm with extension 0.04 μm: |

- NET2 (...)

+ NONDEFAULTRULE NDR1

+ ROUTED METAL2 ( 1 0 ) ( 1 3 ) ( 4 3 ) ( 4 5 ) ;

Figure 4-7 Non-Default rule on wrong way segment

|

NDR4 in the table has a width of 0.16 μm. Width of 0.16 is larger than the first wrongdirection value of 0.12, but is less than or equal to the second wrong-direction value of 0.16, so it will use the wrong-way width of 0.16. In this case both the vertical and horizontal routes will have a width of 0.16 μm with extension of 0.08 μm. |

- NET3 (...)

+ NONDEFAULTRULE NDR4

+ ROUTED METAL2 (1 0) (1 3) (4 3) (4 4) ;

Figure 4-8 Non-Default rule on wrong way segment

Example 4-14 Shielded Net

The following example defines a shielded net:

- my_net ( I1 CLK ) ( BUF OUT )

+ SHIELDNET VSS

+ SHIELDNET VDD

ROUTED

MET2 ( 14000 341440 ) ( 9600 * ) ( * 282400 )

M1M2 ( 2400 * )

+ NOSHIELD MET2 ( 14100 341440 ) ( 14000 * )

+ TAPER MET1 ( 2400 282400 ) ( 240 * )

Defines any nondefault rules used in this design that are not specified in the LEF file. This section can also contain the default rule and LEF nondefault rule definitions for reference. These nondefault rule names can be used anywhere in the DEF NETS section that requires a nondefault rule name.

All vias must be previously defined in the LEF VIA or DEF VIAS sections. Every nondefault rule must specify a width for every layer. If a nondefault rule does not specify a via or via rule for a particular routing-cut-routing layer combination, then there must be a VIARULE GENERATE DEFAULT rule that it inherited for that combination.

DIAGWIDTH diagWidth

Specifies the diagonal width for layerName, when 45-degree routing is used.

Default: 0 (no diagonal routing allowed)

Type: Integer, specified in DEF database units

Specifies that any spacing values that exceed the LEF LAYER ROUTING spacing requirements are "hard" rules instead of "soft" rules. By default, routers treat extra spacing requirements as soft rules that are high cost to violate, but not real spacing violations. However, in certain situations, the extra spacing should be treated as a hard, or real, spacing violation, such as when the route will be modified with a post-process that replaces some of the extra space with metal.

LAYER layerName

Specifies the layer for the various width and spacing values. layerName must be a routing layer. Each routing layer must have at least a minimum width specified.

MINCUTS cutLayerName numCuts

Specifies the minimum number of cuts allowed for any via using the specified cut layer. All vias (generated or fixed vias) used for this nondefault rule must have at least numCuts cuts in the via.

Type: (numCuts) Positive integer

Specifies the number of nondefault rules defined in the NONDEFAULTRULES section.

PROPERTY propName propValue

Specifies a property for this nondefault rule. The propName must be defined as a NONDEFAULTRULE property in the PROPERTYDEFINITIONS section, and the propValue must match the type for propName (that is, integer, real, or string).

Specifies the name for this nondefault rule. This name can be used in the NETS section wherever a nondefault rule name is allowed. The reserved name DEFAULT can be used to indicate the default routing rule used in the NETS section.

SPACING minSpacing

Specifies the minimum spacing for layerName. The LEF LAYER SPACING or SPACINGTABLE definitions always apply; therefore it is only necessary to add a SPACING value if the desired spacing is larger than the LAYER rules already require.

Type: Integer, specified in DEF database units.

VIA viaName

Specifies a previously defined LEF or DEF via to use with this rule.

VIARULE viaRuleName

Specifies a previously defined LEF VIARULE GENERATE to use with this routing rule. If no via or via rule is specified for a given routing-cut-routing layer combination, then a VIARULE GENERATE DEFAULT via rule must exist for that combination, and it is implicitly inherited.

WIDTH minWidth

Specifies the required minimum width allowed for layerName.

Type: Integer, specified in DEF database units

WIREEXT wireExt

Specifies the distance by which wires are extended at vias. Enter 0 (zero) to specify no extension. Values other than 0 must be greater than or equal to half of the routing width for the layer, as defined in the nondefault rule.

Default: Wires are extended half of the routing width

Type: Float, specified in microns

Example 4-15 Nondefault Rules

The following NONDEFAULTRULES statement is based on the assumption that there are VIARULE GENERATE DEFAULT rules for each routing-cut-routing combination, and that the default width is 0.3 μm.

- doubleSpaceRule #Needs extra space, inherits default via rules

+ LAYER metal1 WIDTH 200 SPACING 1000

+ LAYER metal2 WIDTH 200 SPACING 1000

+ LAYER metal3 WIDTH 200 SPACING 1000 ;

- lowerResistance #Wider wires and double cut vias for lower resistance

#and higher current capacity. No special spacing rules,

#therefore the normal LEF LAYER specified spacing rules

#apply. Inherits the default via rules.

+ LAYER metal1 WIDTH 600 #Metal1 is thinner, therefore a little wider

+ LAYER metal2 WIDTH 500

+ LAYER metal3 WIDTH 500

+ MINCUTS cut12 2 #Requires at least two cuts

+ MINCUTS cut23 2 ;

- myRule #Use default width and spacing, change via rules. The

#default via rules are not inherited.

+ LAYER metal1 WIDTH 200

+ LAYER metal2 WIDTH 200

+ LAYER metal3 WIDTH 200

+ VIARULE myvia12rule

+ VIARULE myvia23rule ;

- myCustomRule #Use new widths, spacing and fixed vias. The default

#via rules are not inherited because vias are defined.

+ LAYER metal1 WIDTH 500 SPACING 1000

+ LAYER metal2 WIDTH 500 SPACING 1000

+ LAYER metal3 WIDTH 500 SPACING 1000

+ VIA myvia12_custom1

+ VIA myvia12_custom2

+ VIA myvia23_custom1

+ VIA myvia23_custom2 ;

When the design is a chip rather than a block, the PINS statement describes logical pins, without placement or physical information.

ANTENNAMODEL {OXIDE1 | OXIDE2 | OXIDE3 | OXIDE4}

Specifies the oxide model for the pin. If you specify an ANTENNAMODEL statement, that value affects all ANTENNAGATEAREA and ANTENNA*CAR statements for the pin that follow it until you specify another ANTENNAMODEL statement. The ANTENNAMODEL statement does not affect ANTENNAPARTIAL*AREA and ANTENNADIFFAREA statements because they refer to the total metal, cut, or diffusion area connected to the pin, and do not vary with each oxide model.

Default: OXIDE1, for a new PIN statement

Because DEF is often used incrementally, if an ANTENNA statement occurs twice for the same oxide model, the last value specified is used.

Usually, you only need to specify a few ANTENNA values; however, for a block with six routing layers, it is possible to have six different ANTENNAPARTIAL*AREA values and six different ANTENNAPINDIFFAREA values per pin. It is also possible to have six different ANTENNAPINGATEAREA and ANTENNAPINMAX*CAR values for each oxide model on each pin.

Example 4-16 Antenna Model Statement

The following example describes the OXIDE1 and OXIDE2 models for pin clock1. Note that the ANTENNAPINPARTIALMETALAREA and ANTENNAPINDIFFAREA values are not affected by the oxide values.

+ ANTENNAPINPARTIALMETALAREA 1000 LAYER m1

+ ANTENNAPINDIFFAREA 500 LAYER m1

+ ANTENNAMODEL OXIDE1 #not required, but good practice

+ ANTENNAMAXAREACAR 300 LAYER m1

+ ANTENNAMODEL OXIDE2 #start of OXIDE2 values

+ ANTENNAMAXAREACAR 100 LAYER m1

ANTENNAPINDIFFAREA value [LAYER layerName]

Specifies the diffusion (diode) area to which the pin is connected on a layer. If you do not specify layerName, the value applies to all layers. This is not necessary for output pins.

Type: Integer

Value: Area specified in (DEF database units)2

For more information on process antenna calculation, see Appendix C, "Calculating and Fixing Process Antenna Violations."

ANTENNAPINGATEAREA value [LAYER layerName]

Specifies the gate area to which the pin is connected on a layer. If you do not specify layerName, the value applies to all layers. This is not necessary for input pins.

Type: Integer

Value: Area specified in (DEF database units)2

For more information on process antenna calculation, see Appendix C, "Calculating and Fixing Process Antenna Violations."

ANTENNAPINMAXAREACAR value LAYER layerName

For hierarchical process antenna effect calculation, specifies the maximum cumulative antenna ratio value, using the metal area at or below the current pin layer, excluding the pin area itself. Use this to calculate the actual cumulative antenna ratio on the pin layer, or the layer above it.

Type: Integer

For more information on process antenna calculation, see Appendix C, "Calculating and Fixing Process Antenna Violations."

ANTENNAPINMAXCUTCAR value LAYER layerName

For hierarchical process antenna effect calculation, specifies the maximum cumulative antenna ratio value, using the cut area at or below the current pin layer, excluding the pin area itself. Use this to calculate the actual cumulative antenna ratio for the cuts above the pin layer.

Type: Integer

For more information on process antenna calculation, see Appendix C, "Calculating and Fixing Process Antenna Violations."

ANTENNAPINMAXSIDEAREACAR value LAYER layerName

For hierarchical process antenna effect calculation, specifies the maximum cumulative antenna ratio value, using the metal side wall area at or below the current pin layer, excluding the pin area itself. Use this to calculate the actual cumulative antenna ratio on the pin layer, or the layer above it.

Type: Integer

For more information on process antenna calculation, see Appendix C, "Calculating and Fixing Process Antenna Violations."

ANTENNAPINPARTIALCUTAREA value [LAYER cutLayerName]

Specifies the partial cut area above the current pin layer and inside the macro cell on a layer. If you do not specify layerName, the value applies to all layers. For hierarchical designs, only the cut layer above the I/O pin layer is needed for partial antenna ratio calculation.

Type: Integer

Value: Area specified in (DEF database units)2

For more information on process antenna calculation, see Appendix C, "Calculating and Fixing Process Antenna Violations."

ANTENNAPINPARTIALMETALAREA value [LAYER layerName]

Specifies the partial metal area connected directly to the I/O pin and the inside of the macro cell on a layer. If you do not specify layerName, the value applies to all layers. For hierarchical designs, only the same metal layer as the I/O pin, or the layer above it, is needed for partial antenna ratio calculation.

Type: Integer

Value: Area specified in (DEF database units)2

For more information on process antenna calculation, see Appendix C, "Calculating and Fixing Process Antenna Violations."

ANTENNAPINPARTIALMETALSIDEAREA value [LAYER layerName]

Specifies the partial metal side wall area connected directly to the I/O pin and the inside of the macro cell on a layer. If you do not specify layerName, the value applies to all layers. For hierarchical designs, only the same metal layer as the I/O pin, or the layer above it, is needed for partial antenna ratio calculation.

Type: Integer

Value: Area specified in (DEF database units)2

For more information on process antenna calculation, see Appendix C, "Calculating and Fixing Process Antenna Violations."

COVER pt orient

Specifies the pin's location, orientation, and that it is a part of the cover macro. A COVER pin cannot be moved by automatic tools or by interactive commands. If you specify a placement status for a pin, you must also include a LAYER statement.

DIRECTION {INPUT | OUTPUT | INOUT | FEEDTHRU}

Specifies the pin type. Most current tools do not usually use this keyword. Typically, pin directions are defined by timing library data, and not from DEF.

Value: Specify one of the following:

|

Pin that can accept signals going either in or out of the cell. |

||

FIXED pt orient

Specifies the pin's location, orientation, and that it's location cannot be moved by automatic tools, but can be moved by interactive commands. If you specify a placement status for a pin, you must also include a LAYER statement.

GROUNDSENSITIVITY groundPinName

Specifies that if this pin is connected to a tie-low connection (such as 1'b0 in Verilog), it should connect to the same net to which groundPinName is connected.

groundPinName must match another pin in this PINS section that has a + USE GROUND attribute. The ground pin definition can follow later in this PINS section; it does not have to be defined before this pin definition. It is a semantic error to put this attribute on an existing ground pin. For an example, see Example 4-18.

Note: GROUNDSENSITIVITY is useful only when there is more than one ground net connected to pins in the PINS section. By default, if there is only one net connected to all + USE GROUND pins, the tie-low connections are already implicitly defined (that is, tie-low connections are connected to the same net as any ground pin).

MASK maskNum

Specifies which mask from double or triple patterning to use for the specified shape. The maskNum variable must be a positive integer - most applications support values of 1, 2, or 3 only. Shapes without any defined mask do not have a mask set (are uncolored).

MASK viaMaskNum

Specifies which mask for double or triple patterning lithography is to be applied to via shapes on each layer.

The viaMaskNum variable is a hex-encoded three digit value of the form:

<topMaskNum><cutMaskNum><bottomMaskNum>

For example, MASK 113 means the top metal and cut layer maskNum is 1, and the bottom metal layer maskNum is 3. A value of 0 indicates that the shape on that layer does not have a mask assignment (is uncolored), so 013 means the top layer is uncolored. If either the first or second digit is missing, they are assumed to be 0, so 013 and 13 mean the same thing. Most applications support maskNums of 0, 1, 2, or 3 for double or triple patterning.

The topMaskNum and bottomMaskNum variables specify which mask the corresponding metal shape belongs to. The via-master metal mask values have no effect.

For the cut-layer, the cutMaskNum variable defines the mask for the bottom-most, then the left-most cut in the North (R0) orientation. For multi-cut vias, the via-instance cut masks are derived from the via-master cut mask values. The via-master must have a mask defined for all of the cut shapes and every via-master cut mask is "shifted" (from 1 to 2 and 2 to1 for two mask layers, and from 1 to 2, 2 to 3, and 3 to1 for three mask layers), so the lower-left cut matches the cutMaskNum value. See Example 4-17.

Similarly, for the metal layer, the topMaskNum/bottomMaskNum would define the mask for the bottom-most, then leftmost metal shape. For multiple disjoint metal shapes, the via-instance metal masks are derived from the via-master metal mask values. The via-master must have a mask defined for all of the metal shapes, and every via-master metal mask is "shifted" (1->2, 2->1 for two mask layers, 1->2, 2->3, 3->1 for three mask layers) so the lower-left cut matches the topMaskNum/bottomMaskNum value.

Shapes without any defined mask, that need to be assigned, can be assigned to an arbitrary choice of mask by applications.

Example 4-17 Multi-Mask Patterns for Pins

The following example shows via master masks:

+ LAYER M1 MASK 2 ( -25 0 ) ( 25 50 ) #m1 rectangle is on mask 2

+ LAYER M2 ( -10 0 ) ( 10 75 ) #m2 rectangle, no mask

+ VIA VIA1 MASK 031 ( 0 25 ) #via1 with mask 031

...

The VIA1 via will have:

|

no mask set for the top metal shape (topMaskNum is 0 in the 031 value) |

|

MASK 1 for the bottom metal shape (botMaskNum is 1 in the 031 value) |

|

the bottom-most, and then the left-most cut of the via-instance is MASK 3. The mask for the other cuts of the via-instance are derived from the via-master by "shifting" the via-master cut masks to match. So if the via-master's bottom-left cut is MASK 1, then the via-master cuts on MASK 1 become MASK 3 for the via-instance. Similarly cuts on 2 shift to 1, and cuts on 3 shift to 2. See Figure 4-9. |

Figure 4-9 Multi-Mask Patterns for Pins

NETEXPR "netExprPropName defaultNetName"

Specifies a net expression property name (such as power1 or power2) and a default net name. If netExprPropName matches a net expression property higher up in the netlist (for example, in Verilog, VHDL, or OpenAccess), then the property is evaluated, and the software identifies a net to which to connect this pin. If the property does not exist, defaultNetName is used for the net name.

netExprPropName must be a simple identifier in order to be compatible with other languages, such as Verilog and CDL. Therefore, it can only contain alphanumeric characters, and the first character cannot be a number. For example, power2 is a legal name, but 2power is not. You cannot use characters such as $ and !. The defaultName can be any legal DEF net name.

If more than one pin connects to the same net, only one pin should have a NETEXPR added to it. It is redundant and unnecessary to add NETEXPR to every ground pin connected to one ground net, and it is illegal to have different NETEXPR values for pins connected to the same net.

Example 4-18 Net Expression and Supply Sensitivity

The following PINS statement defines sensitivity and net expression values for five pins in the design myDesign:

- in1 + NET myNet

...

+ SUPPLYSENSITIVITY vddpin1 ; #If in1 is connected to 1'b1, use

#net that is connected to vddpin1.

#No GROUNDSENSITIVITY is needed because

#only one ground net is used by PINS.

#Therefore, 1'b0 implicitly means net

#from any +USE GROUND pin.

- vddpin1 + NET VDD1 + USE POWER

...

+ NETEXPR "power1 VDD1" ; #If an expression named power1 is defined in

#the netlist, use it to fine the net.

#Otherwise, use net VDD1.

- vddpin2 + NET VDD2 + USE POWER

...

+ NETEXPR "power2 VDD2" ; #If an expression named power2 is defined in

#the netlist, use it to find the net.

# Otherise, use net VDD2.

- gndpin1 + NET GND + USE GROUND

...

+ NETEXPR "gnd1 GND" ; #If an expression named gnd1 is defined in

#the netlist, use it to find net

#connection. Otherwise, use net GND.

Specifies the number of pins defined in the PINS section.

pinName + NET netName

Specifies the name for the external pin, and the corresponding internal net (defined in NETS or SPECIALNETS statements).

PLACED pt orient

Specifies the pin's location, orientation, and that it's location is fixed, but can be moved during automatic layout. If you specify a placement status for a pin, you must also include a LAYER statement.

Indicates that the following LAYER, POLYGON, and VIA statements are all part of one PORT connection, until another PORT statement occurs. If this statement is missing, all of the LAYER, POLYGON, and VIA statements are part of a single implicit PORT for the PIN.

This commonly occurs for power and ground pins. All of the shapes of one port (rectangles, polygons, and vias) should already be connected with just the port shapes; therefore, the router only needs to connect to one of the shapes for the port. Separate ports should each be connected by routing inside the block (and each DEF PORT should map to a single LEF PORT in the equivalent LEF abstract for this block).

The syntax for describing PORT statements is defined as follows:

[[+ PORT]

[ + LAYER layerName

[ SPACING minSpacing

| DESIGNRULEWIDTH effectiveWidth]

pt pt

| + POLYGON layerName

[ SPACING minSpacing

| DESIGNRULEWIDTH effectiveWidth]

pt pt pt

| + VIA viaName pt

] ...

]

|

LAYER layerName pt pt |

||

|

Specifies the routing layer used for the pin, and the pin geometry on that layer. If you specify a placement status for a pin, you must include a LAYER statement. |

||

|

POLYGON layerName pt pt pt |

||

|

Each POLYGON statement defines a polygon generated by connecting each successive point, and then the first and last points. The pt syntax corresponds to a coordinate pair, such as x y. Specify an asterisk (*) to repeat the same value as the previous x or y value from the last point. (See Example 4-20.) |

||

|

SPACING minSpacing |

||

|

Specifies the minimum spacing allowed between this pin and any other routing shape. This distance must be greater than or equal to minSpacing. If you specify SPACING, you cannot specify DESIGNRULEWIDTH. (See Example 4-21. |

||

|

DESIGNRULEWIDTH effectiveWidth |

||

|

Specifies that this pin has a width of effectiveWidth for the purpose of spacing calculations. If you specify DESIGNRULEWIDTH, you cannot specify SPACING. As a lot of spacing rules in advanced nodes no longer just rely on wire width, DESIGNRULEWIDTH is not allowed for 20nm and below nodes. (See Example 4-21. |

||

|

VIA viaName pt |

||

|

Places the via named viaName at the specified (x y) location (pt). viaName must be a previously defined via in the DEF VIAS or LEF VIA section. |

||

Example 4-19 Port Example

Assume a block that is 5000 x 5000 database units with a 0,0 origin in the middle of the block. If you have the following pins defined, Figure 4-10 illustrates how pin BUSA[0] is created for two different placement locations and orientations:

- BUSA[0] + NEY BUSA[0] + DIRECTION IN{UT + USE SIGNAL

+ LAYER M1 ( -25 0 ) ( 25 50 ) #m1, m2, and via12

+ LAYER M2 ( -10 0 ) ( 10 75 )

+ VIA via12 ( 0 25 )

+ PLACED ( 0 -2500 ) N ; #middle of bottom side

- VDD + NET VDD + DIRECTION INOUT + USE POWER + SPECIAL

+ PORT

+ LAYER M2 ( -25 0 ) ( 25 50 )

+ PLACED ( 0 2500 ) S #middle of top side

+ PORT

+ LAYER M1 (-25 0 ) ( 25 50 )

+ PLACED ( -2500 0 ) E #middle of left side

+ PORT

+ LAYER M1 ( -25 0 ) ( 25 50 )

+ PLACED ( 2500 0 ) W ; #middle of right side

Figure 4-10 Port Illustration

Example 4-20 Port Statement With Polygon

The following PINS statement creates a polygon with a 45-degree angle:

- myPin3 + NET myNet1 + DIRECTION INPUT

+ PORT

+ POLYGON metal1 ( 0 0 ) ( 100 100 ) ( 200 100 ) ( 200 0 ) #45-degree angle

+ FIXED ( 10000 5000 ) N ;

...

Example 4-21 Design Rule Width and Spacing Rules

The following statements create spacing rules using the DESIGNRULEWIDTH and SPACING statements:

- myPin1 + NET myNet1 + DIRECTION INPUT

+ LAYER metal1

DESIGNRULEWIDTH 1000 #Pin is effectively 1000 dbu wide

( -100 0 ) ( 100 200 ) #Pin is 200 x 200 dbu

+ FIXED ( 10000 5000 ) S ;

- myPin2 + NET myNet2 + DIRECTION INPUT

+ LAYER metal1

SPACING 500 #Requires >= 500 dbu spacing

( -100 0 ) ( 100 200 ) #Pin is 200 x 200 dbu

+ COVER ( 10000 5000 ) S ;

- myPin3 + NET myNet1 #Pin with two shapes

+ DIRECTION INPUT

+ LAYER metal2 ( 200 200 ) ( 300 300 ) #100 x 100 dbu shape

+ POLYGON metal1 ( 0 0 ) ( 100 100 ) ( 200 100 ) ( 200 0 ) #Has 45-degree edge

+ FIXED ( 10000 5000 ) N ;

Identifies the pin as a special pin. Regular routers do not route to special pins. The special router routes special wiring to special pins.

SUPPLYSENSITIVITY powerPinName

Specifies that if this pin is connected to a tie-high connection (such as 1'b1 in Verilog), it should connect to the same net to which powerPinName is connected.

powerPinName must match another pin in this PINS section that has a + USE POWER attribute. The power pin definition can follow later in this PINS section; it does not have to be defined before this pin definition. It is a semantic error to put this attribute on an existing power pin. For an example, see Example 4-18.

Note: POWERSENSITIVITY is useful only when there is more than one power net connected to pins in the PINS section. By default, if there is only one net connected to all + USE POWER pins, the tie-high connections are already implicitly defined (that is, tie-high connections are connected to the same net as the single power pin).

USE {ANALOG | CLOCK | GROUND | POWER | RESET | SCAN | SIGNAL | TIEOFF}

Specifies how the pin is used.

Default: SIGNAL

Value: Specify one of the following:

|

Pin is used for connectivity to the chip-level ground distribution network. |

||

|

Pin is used for connectivity to the chip-level power distribution network. |

||

For extra non-bus bit pin names, use the following syntax:

pinname.extraN

N is a positive integer, incremented as the physical pins are added

For example:

PINS n ;